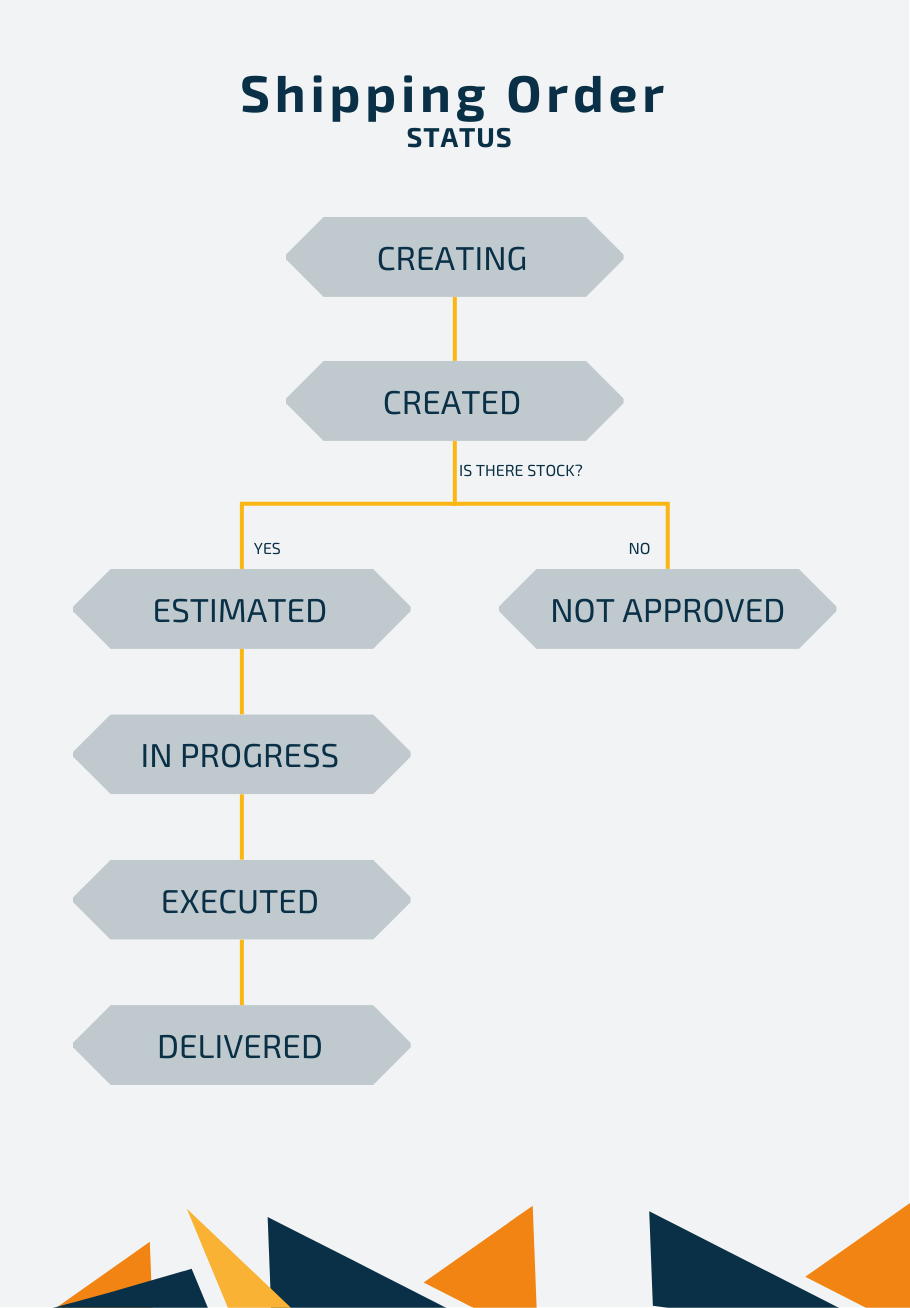

Shipping Order Status

Creating

This is the “draft” status of a shipping order, allowing you to edit the information before the system checks if the conditions to fulfill the order are met. To move to the next status, you need to use the “Send to picking” button.

Created

After using the “Send to picking” button, the order moves to the Created status. This indicates that the system is checking if there is enough stock in the warehouse to fulfill the order. From here, it can move to one of two statuses: Estimated or Not Approved.

Estimated

The system has validated that there is sufficient stock. If the items in the order have a lot but it wasn't assigned during the "Creating" status, the system will assign a lot based on FEFO (First-Expire, First-Out) and FIFO (First-In, First-Out) rules. Once it reaches this status, the Shipping Order appears in the cockpit for you to plan its picking and packing.

Note: The statuses in the Cockpit related to picking and packing differ from those that appear in the Shipping Orders, as they only show that specific process (Picking or Packing) and not the order as a whole.

Not Approved

It has been verified that there is not enough stock. You should proceed to correct or cancel the lines in the Shipping Order. You can find more information about this in this article:

In Progress

After the operator starts the Picking process, the order moves to the “In Progress” status.

Executed

This status is used only when, in the shipping processes, you indicated that you do not want the order to be shipped automatically after packing (for more information about this configuration, see this article: Shipping Processes).

You must manually use the Ship button so that the stock is removed from the system and the invoice is issued (if you have integration with an invoicing software).

Delivered

The shipping process has ended: the stock used to fulfill the order has been removed from the warehouse stock, and the process has been completed.

Canceled

The shipping order has been canceled, along with its lines. If picking and/or packing has already been done, the stock collected by the operator and indicated to the system remains in the chosen packing location (if none was chosen by the operator, the system places it in the default assigned packing location). To be able to use this stock again, it must be put away in a picking location.